Fiberglass Pipes Market: Global Industry Analysis & Forecast 2033

Global Fiberglass Pipes Market Overview (2025–2033)

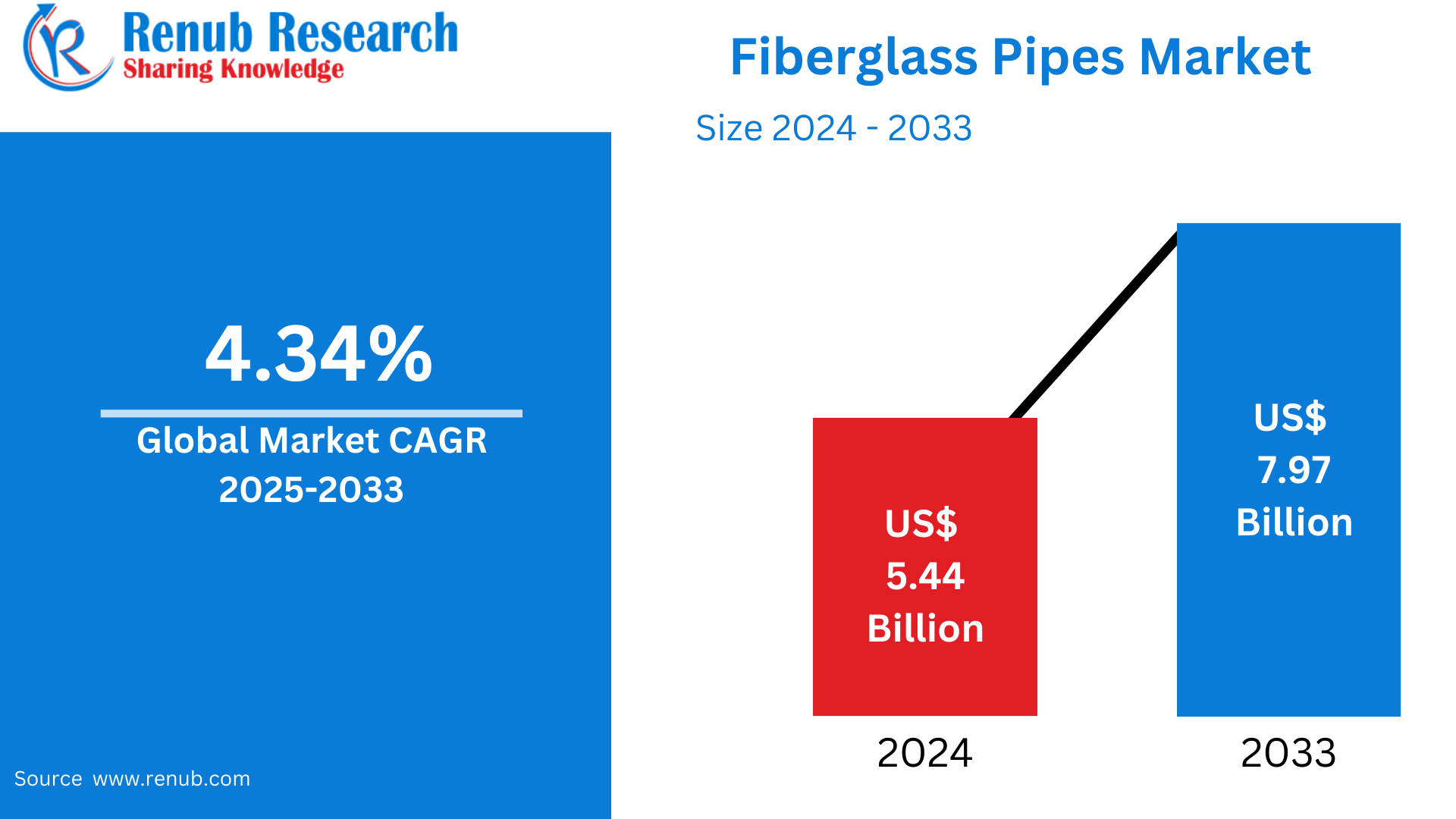

According To Renub Research global fiberglass pipes market is demonstrating steady and resilient growth as industries increasingly seek durable, corrosion-resistant, and lightweight piping solutions. In 2024, the market was valued at US$ 5.44 billion and is projected to reach US$ 7.97 billion by 2033, expanding at a compound annual growth rate of 4.34% from 2025 to 2033. This growth is primarily driven by rising demand from oil & gas, chemical processing, water treatment, sewage, and irrigation sectors. Fiberglass pipes are gaining preference over conventional metal and concrete pipes due to their superior performance in harsh environments, reduced maintenance requirements, and longer operational lifespan.

Definition and Technical Characteristics of Fiberglass Pipes

Fiberglass pipes, commonly referred to as fiberglass-reinforced plastic (FRP) pipes, are composite structures manufactured using a polymer resin matrix reinforced with glass fibers. The most widely used resins include polyester, vinyl ester, and epoxy. This combination provides high mechanical strength, excellent chemical resistance, and a favorable strength-to-weight ratio. Fiberglass pipes are non-corrosive, electrically non-conductive, and capable of withstanding extreme temperatures and pressures, making them suitable for demanding industrial and infrastructure applications.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=fiberglass-pipes-market-p.php

Application Scope Across End-Use Industries

Fiberglass pipes are widely used across multiple industries due to their versatility and reliability. In oil and gas operations, they are deployed to transport corrosive fluids, hydrocarbons, and injection water. Chemical processing facilities rely on fiberglass pipes for handling aggressive chemicals and high-temperature liquids. Water and wastewater treatment plants utilize these pipes for raw water intake, treated water distribution, and sewage transport. Additionally, fiberglass pipes are increasingly used in marine applications, power generation facilities, and agricultural irrigation systems, where resistance to corrosion and lightweight construction are essential.

Rising Demand from the Oil and Gas Industry

The oil and gas sector remains one of the largest consumers of fiberglass pipes. These pipes offer significant advantages in both onshore and offshore operations, where exposure to corrosive substances, saline environments, and extreme weather conditions is common. Fiberglass pipes provide longer service life and lower maintenance costs compared to traditional steel pipes. As global energy demand continues to rise and exploration activities expand, investments in durable pipeline infrastructure are increasing, directly supporting the growth of the fiberglass pipes market.

Infrastructure Development in Emerging Economies

Rapid urbanization and infrastructure expansion in emerging economies, particularly in Asia-Pacific, the Middle East, and parts of Africa, are fueling demand for fiberglass pipes. Governments are investing heavily in water supply networks, sewage systems, industrial corridors, and irrigation projects. Fiberglass pipes are increasingly favored due to their long service life, resistance to chemical degradation, and ease of installation. Their ability to perform reliably in aggressive soil and environmental conditions makes them well suited for large-scale infrastructure projects where lifecycle cost efficiency is critical.

Technological Advancements and Product Innovation

Continuous advancements in materials science and manufacturing technologies have significantly improved the performance of fiberglass pipes. Innovations have led to the development of advanced products such as Glass Reinforced Epoxy (GRE) and Glass Reinforced Plastic (GRP) pipes, which offer enhanced pressure tolerance, thermal resistance, and durability. Automation in production processes has also improved quality consistency and reduced manufacturing costs. These technological improvements allow manufacturers to deliver customized solutions tailored to specific industrial requirements, further accelerating market adoption.

High Initial Cost as a Key Market Challenge

Despite their long-term advantages, fiberglass pipes face challenges related to high initial costs. Compared to traditional materials such as steel, ductile iron, or PVC, fiberglass pipes require higher upfront investment. Installation often demands specialized equipment and skilled labor, increasing overall project costs. In cost-sensitive markets or small-scale projects, this can limit adoption, even though fiberglass pipes offer lower maintenance and replacement costs over their lifespan.

Environmental and Recycling Concerns

Environmental considerations present another challenge for the fiberglass pipes industry. The production process involves non-renewable raw materials and may generate volatile organic compound emissions. Additionally, recycling fiberglass pipes is complex due to their composite structure, making end-of-life disposal more challenging. As environmental regulations tighten globally, manufacturers are under pressure to develop more sustainable production methods and explore viable recycling or reuse solutions to reduce environmental impact.

GRE Fiberglass Pipes Market

Glass Reinforced Epoxy pipes represent a high-performance segment within the fiberglass pipes market. GRE pipes are known for their exceptional corrosion resistance, thermal stability, and ability to withstand high pressures. They are extensively used in oil and gas, marine, and chemical processing applications, particularly in offshore environments. Their lightweight nature reduces transportation and installation costs while maintaining superior mechanical strength, making them ideal for demanding industrial applications.

E-Glass Fiberglass Pipes Market

E-glass fiberglass pipes utilize electrical-grade glass fibers that offer strong insulation properties and high mechanical performance. These pipes are widely used in chemical processing, electrical, and telecommunications industries. Their non-conductive nature and resistance to corrosion make them suitable for applications involving both chemical exposure and electrical safety requirements. E-glass fibers contribute to durability and lightweight construction, positioning these pipes as a preferred alternative to metallic systems.

Oil and Gas End-Use Segment Analysis

In oil and gas applications, fiberglass pipes are valued for their ability to transport corrosive fluids such as crude oil, saltwater, and gas with minimal maintenance. They are commonly used in gathering lines, injection systems, and offshore platform piping. As exploration moves into deeper and more challenging environments, the need for high-performance, corrosion-resistant piping systems continues to grow, strengthening the role of fiberglass pipes across upstream and downstream operations.

Sewage and Wastewater Applications

Sewage and wastewater treatment systems benefit significantly from the use of fiberglass pipes. These pipes resist chemical and microbial degradation, ensuring long service life even under continuous exposure to aggressive waste streams. Their smooth internal surfaces reduce friction losses and prevent sediment buildup, improving flow efficiency. With increasing urban population and investment in sanitation infrastructure, fiberglass pipes are becoming a preferred solution for modern wastewater management.

Irrigation and Agricultural Applications

Fiberglass pipes offer a reliable and durable solution for irrigation systems, particularly in regions with intensive agricultural activity. Their resistance to fertilizers, chemicals, ultraviolet radiation, and environmental stress makes them suitable for long-term outdoor use. Lightweight construction simplifies installation, while reduced leakage improves water efficiency. As global food demand rises and precision agriculture gains momentum, fiberglass pipes are playing an increasingly important role in modern irrigation infrastructure.

United States Fiberglass Pipes Market Overview

The United States fiberglass pipes market is mature and technologically advanced, with strong demand from oil and gas, chemical processing, water management, and industrial infrastructure sectors. Aging infrastructure replacement programs and regulatory emphasis on corrosion-resistant materials are driving adoption. Growth is also supported by applications in renewable energy and water recycling. Continuous research and development, along with government-backed infrastructure investments, contribute to sustained market expansion.

France Fiberglass Pipes Market Overview

France’s fiberglass pipes market is driven by demand from municipal water supply, wastewater treatment, and energy sectors. The country’s focus on sustainable urban development and green construction has increased the adoption of corrosion-resistant composite materials. Fiberglass pipes are being integrated into smart water systems and renewable energy projects, supported by regulatory frameworks that encourage environmental protection and long-term infrastructure resilience.

India Fiberglass Pipes Market Overview

India is experiencing rapid growth in the fiberglass pipes market, supported by urbanization, infrastructure development, and agricultural expansion. Government initiatives aimed at improving water supply, sanitation, and irrigation are major growth drivers. Fiberglass pipes offer a cost-effective and durable alternative to traditional materials, particularly in regions with challenging soil and climate conditions. Growing domestic manufacturing and international collaborations are enhancing product availability and affordability.

Saudi Arabia Fiberglass Pipes Market Overview

Saudi Arabia represents a significant market for fiberglass pipes due to extensive oil and gas operations and large-scale water infrastructure projects. Harsh desert conditions make corrosion-resistant and lightweight fiberglass pipes highly suitable. National development initiatives focused on infrastructure expansion, desalination, and industrial diversification are accelerating market growth. Increasing local manufacturing capacity further strengthens the country’s position in the regional fiberglass pipes market.

Market Segmentation Overview

The fiberglass pipes market is segmented by product type into GRE pipes, GRP pipes, and other variants. Based on fiber type, the market includes E-glass, T-glass, S-glass, R-glass, and others. End-use industries include oil and gas, chemicals, sewage, irrigation, and additional industrial applications. Geographically, the market spans North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, with varying growth patterns influenced by industrial activity and infrastructure investment.

Competitive Landscape and Key Players

The competitive landscape of the fiberglass pipes market includes global manufacturers and regional specialists focused on product innovation and capacity expansion. Key players operating in the market include PPG Industries, Inc., Future Pipe Industries, Saudi Arabian Amiantit Co, Amiblu Holding GmbH, Chemical Process Piping Pvt. Ltd., Russel Metals Inc., ANDRONACO INDUSTRIES, and Gruppo Sarplast. These companies focus on expanding production capacity, developing advanced materials, and serving diverse industrial needs.

Future Market Outlook

The global fiberglass pipes market is expected to maintain stable growth through 2033 as industries increasingly prioritize durability, efficiency, and lifecycle cost savings. Continued investment in oil and gas infrastructure, water management, and urban development will sustain demand. Technological innovation, coupled with a growing emphasis on sustainability and performance reliability, will further strengthen the role of fiberglass pipes as a critical component of modern industrial and infrastructure systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness