Cap Mould Factory Supplied By qhpreformmould Guarantees Consistent Operational Quality

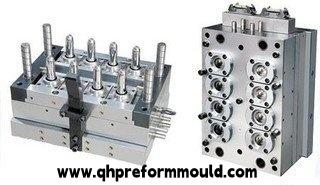

A Qihong Cap Mould Factory is a cornerstone for industries seeking precision and reliability in production. From the very first step, clients evaluate how designs translate into functional components that maintain quality under repeated use. Products originating from a well-managed factory promise consistent dimensions, uniform finish, and predictable performance, ensuring that assembly and downstream processes proceed without interruption. Manufacturers who prioritize disciplined procedures create a tangible advantage in efficiency and quality perception.

Design development in a professional setting requires balance between technical accuracy and practical usability. Specialists monitor surface uniformity, wall thickness, and internal geometries to prevent defects and optimize material distribution. Every refinement is guided by performance goals, aiming to provide molds that not only produce flawless products but also extend service life for both equipment and operators.

Manufacturing workflows emphasize precision and repeatability. Standardized sequences, careful inspections, and controlled tolerances contribute to results that satisfy stringent requirements. Smooth internal surfaces and accurate external contours simplify demolding, reducing assembly time and preventing material waste. These practices illustrate the importance of disciplined production over superficial aesthetics, highlighting operational integrity as a key differentiator.

Material selection plays a critical role. Components are chosen for stability under temperature fluctuations, resistance to abrasion, and long-term durability. Rather than focusing on cosmetic enhancements, the emphasis is placed on predictable behavior and dimensional fidelity. Qihong exemplifies a commitment to sourcing materials that align with performance objectives while maintaining operational reliability.

Installation and maintenance are practical priorities. Mold designs consider ease of alignment, accessibility for inspection, and straightforward cleaning. Operators benefit from uniform structures, which reduce the potential for misalignment and facilitate efficient upkeep. This thoughtful approach increases production consistency and minimizes operational downtime.

Communication and documentation are structured to support decision-making. Clear specifications, dimensional drawings, and material descriptions enable buyers to assess suitability without ambiguity. Users can make confident choices based on functional performance rather than marketing statements alone.

Iterative feedback loops further enhance quality. Observations from production lines inform incremental improvements in geometry, surface finish, and component interactions. Adjustments based on real-world performance ensure molds remain relevant and capable of delivering precise products consistently.

For those interested in exploring available models, technical specifications, and ordering information, complete details are available at https://www.qhpreformmould.com/product/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness