Outdoor Socket Box Solutions From NANTE

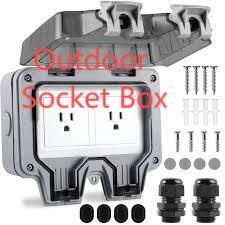

Modern outdoor electrical projects demand equipment that combines protection, accessibility, and long service life, so an Outdoor Socket Box must withstand rain, dust, UV exposure, and mechanical stress while remaining simple for technicians to inspect, and planners also expect the Outdoor Socket Box to support safe connections that reduce downtime and simplify routine maintenance. These expectations define how outdoor socket systems are specified, installed, and maintained across industrial, commercial, and temporary applications.

Environmental challenges shaping outdoor installations

Outdoor power access points face harsher conditions than indoor systems. Temperature fluctuations cause expansion and contraction, moisture threatens insulation integrity, and airborne contaminants accelerate corrosion. In public or industrial spaces, socket boxes must also resist impact and tampering. Understanding these environmental pressures helps engineers choose appropriate enclosure thickness, sealing strategies, and mounting locations that preserve safety and performance over time.

Materials, sealing methods, and protection ratings

The enclosure material determines durability. Polymer and composite housings offer excellent corrosion resistance and electrical insulation, while metal enclosures provide superior mechanical strength. Sealing systems — gaskets, compression lids, and locking covers — are equally critical. Properly designed seals prevent water ingress without making access difficult. Selecting the right IP or NEMA rating ensures the enclosure matches site exposure, whether it is a sheltered outdoor wall or an open construction area.

Installation practices that preserve long-term reliability

Correct installation is essential for maintaining protection ratings. Cable entry points should use certified glands or conduit fittings that maintain sealing integrity. Conductors must be routed to avoid sharp bends and mechanical strain, while terminals should be tightened to specified torque values. Grounding and bonding should be completed before energizing the circuit, and clear labeling of outlets and feeds helps prevent errors during later servicing or expansion.

Nante Outdoor Socket Box Design Philosophy

Nante focuses on practical modularity and field efficiency. Standardized mounting patterns, interchangeable socket inserts, and service-friendly covers allow technicians to replace worn components without removing the entire enclosure. This approach reduces repair time and minimizes spare inventory requirements, especially on sites with multiple outdoor access points. Modular design also supports future upgrades as power needs evolve.

Inspection, maintenance, and lifecycle management

Outdoor socket boxes benefit from routine inspection. Visual checks should look for gasket wear, latch integrity, and signs of moisture intrusion. Electrical inspections — such as contact resistance measurements and thermal imaging — help identify developing issues before failure occurs. Keeping a simple maintenance log provides valuable insight into wear patterns and supports smarter replacement planning. Over time, proactive care extends service life and reduces unexpected outages.

In summary, outdoor socket systems succeed when enclosure design, installation quality, and maintenance planning work together. By prioritizing environmental protection, clear internal organization, and modular serviceability, project teams can achieve safer and more reliable outdoor power access. For product options and configuration details, visit https://www.nante.com/product to explore suitable solutions for your application.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness