Is Nbcbdz Shaping New Paths in EI Transformer Factory Work?

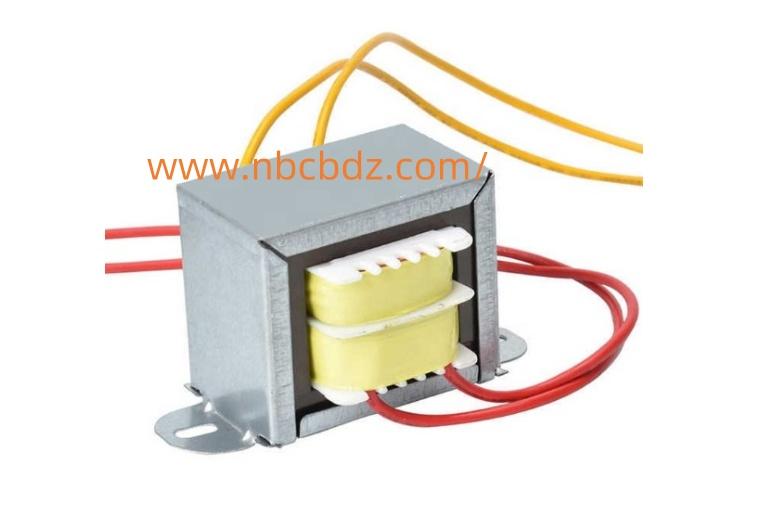

In today's fast-moving electrical landscape, EI Transformer Factory solutions are often judged by reliability, communication, and the ability to adapt to real project needs, and Nbcbdz is a name frequently discussed in this context. Rather than focusing on bold claims, this discussion centers on practical manufacturing thinking, steady cooperation, and how careful processes can support consistent outcomes for diverse applications.

Modern transformer production is no longer only about assembling components. It involves coordination between design understanding, material selection, and production planning. Manufacturers that value clear communication tend to build smoother partnerships, because expectations are aligned from the beginning. This approach helps clients feel confident when integrating transformers into broader systems such as control cabinets, industrial equipment, or energy management setups.

Another important aspect is flexibility. Project requirements often vary, and manufacturers who are open to adjustment can support more efficient development cycles. This may include adapting designs to fit space limitations, matching specific electrical environments, or aligning production schedules with downstream assembly plans. A collaborative mindset can reduce friction and allow both sides to focus on functional goals rather than unnecessary revisions.

Quality awareness also plays a role in long-term cooperation. While perfection is never claimed, consistent attention to process discipline can reduce avoidable issues. From material handling to assembly flow, each step influences the final product. Teams that emphasize internal checks and orderly workflows often deliver components that integrate more smoothly into customer systems, helping reduce follow-up concerns.

Beyond production itself, service attitude matters. Clear responses, timely updates, and a willingness to discuss technical details create trust. Clients value partners who listen carefully and respond with practical suggestions rather than generic answers. Over time, this exchange of information supports better alignment and more efficient future projects.

Sustainability considerations are becoming part of everyday conversations as well. Responsible sourcing, mindful use of materials, and efficient manufacturing practices reflect an awareness of broader industry responsibilities. While such efforts may not always be visible in a single product, they influence how a company positions itself within the supply chain and how partners perceive long-term stability.

For engineers and sourcing professionals, selecting a transformer manufacturer is often about balance. Technical capability, communication style, adaptability, and steady output all contribute to a workable partnership. When these elements come together, collaboration feels less like a transaction and more like an ongoing exchange aimed at shared objectives.

As industries continue to evolve, thoughtful manufacturing relationships remain essential. By focusing on clarity, cooperation, and practical execution, companies can better support the systems that rely on their components. For readers interested in seeing how these ideas are reflected in real manufacturing practice, a closer look online may offer useful perspective.

If you are curious about approaches, projects, and manufacturing philosophy that emphasize steady cooperation, consider taking a moment to visit https://www.nbcbdz.com/product/ and see what insights await your next click.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness