U.S. Epoxy Resin Market Analysis by Type, Form & End Use 2026–34

United States Epoxy Resin Market Size and Forecast 2026–2034

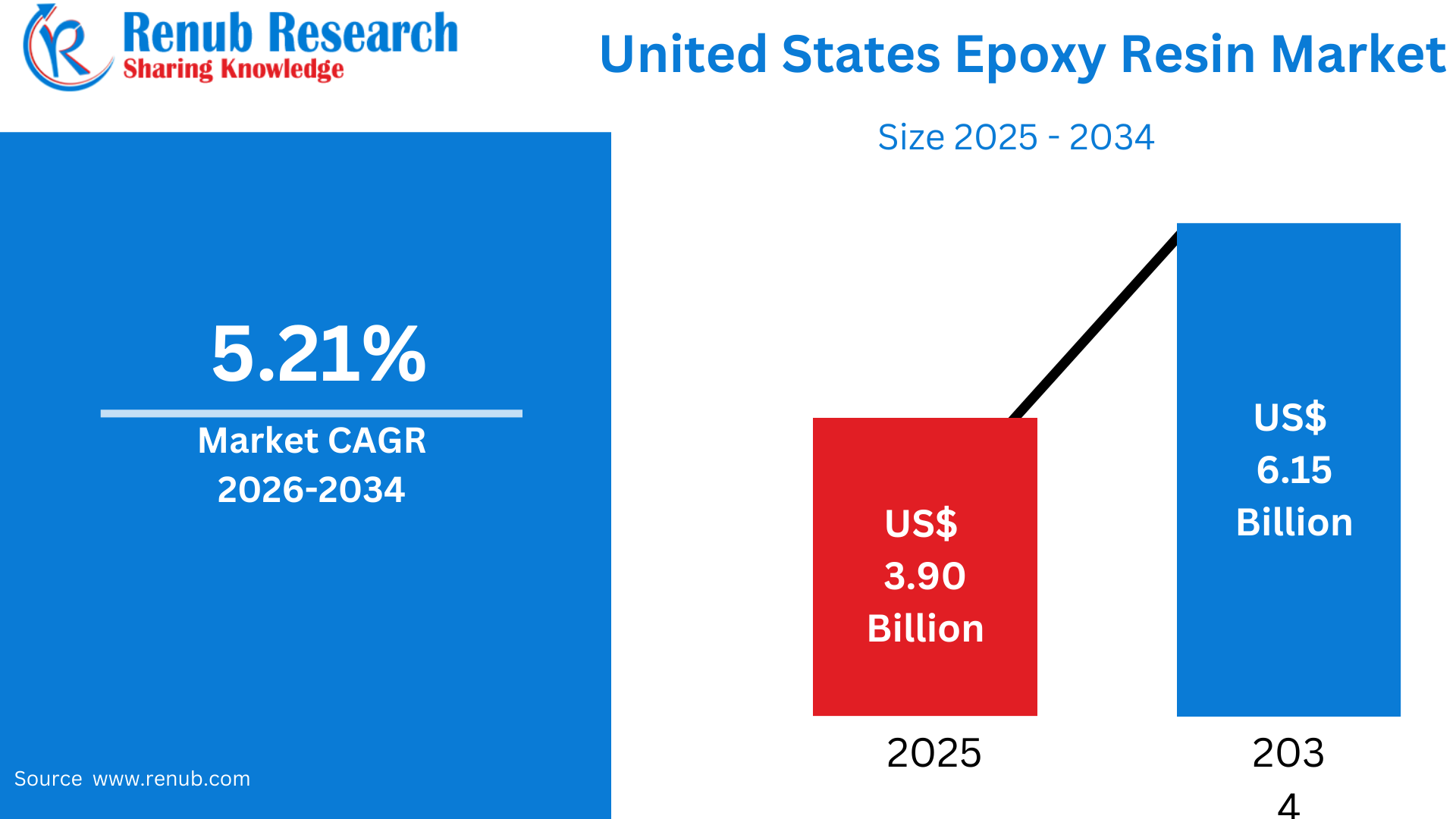

According to Renub Research United States epoxy resin market is projected to experience stable and sustained growth over the forecast period from 2026 to 2034. Market revenue is expected to rise from approximately US$ 3.90 billion in 2025 to nearly US$ 6.15 billion by 2034, reflecting a compound annual growth rate (CAGR) of 5.21%. This expansion is driven by increasing demand from construction, automotive, aerospace, electronics, wind energy, and general industrial sectors. Epoxy resins have become indispensable due to their superior mechanical strength, chemical resistance, adhesion, and thermal stability. As industries prioritize lightweight materials, durability, and long service life, epoxy-based composites, coatings, and adhesives are gaining wider acceptance across the U.S. manufacturing and infrastructure landscape.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=united-states-epoxy-resin-market-p.php

United States Epoxy Resin Market Outlook

Epoxy resin is a broad class of high-performance thermosetting polymers produced through the reaction of epoxide groups with curing agents. Once cured, epoxy resins form rigid, cross-linked structures that offer exceptional performance in demanding environments. These materials are widely used in coatings, adhesives, laminates, encapsulation, flooring systems, and structural composites. Their strong bonding capability with metals, concrete, wood, and advanced composites makes them suitable for diverse industrial and consumer applications.

In the United States, epoxy resins have gained strong traction due to their reliability, versatility, and adaptability to advanced material requirements. The rising use of lightweight composite structures in automotive and aerospace manufacturing is a major contributor to market growth. Epoxy-based protective coatings are also widely applied to safeguard infrastructure, pipelines, storage tanks, and industrial equipment against corrosion, abrasion, and environmental stress. In addition, epoxy resins are increasingly used in home improvement and DIY projects, including decorative flooring, countertops, waterproofing, and artistic applications. The expansion of renewable energy installations, particularly wind power, has further reinforced the role of epoxy resins in turbine blade manufacturing. Continuous innovation and industrial expansion ensure that epoxy resin remains a foundational material within the U.S. economy.

Increasing Demand for High-Performance Materials Across Industries

One of the primary growth drivers of the U.S. epoxy resin market is the rising need for high-performance materials across multiple industrial sectors. Construction, automotive, aerospace, marine, and electronics industries increasingly require materials that can withstand mechanical stress, chemical exposure, and harsh environmental conditions. Epoxy resins meet these requirements through their excellent adhesion, structural strength, and corrosion resistance, making them essential for coatings, structural bonding, composites, and industrial flooring systems.

Infrastructure modernization initiatives across highways, bridges, industrial facilities, and commercial buildings are significantly boosting demand for epoxy-based repair and protection solutions. In automotive and aerospace applications, epoxy resins contribute to the development of lightweight components that improve fuel efficiency, reduce emissions, and enhance safety. Strategic investments by major chemical manufacturers, including expansion activities by Aditya Birla Group in the United States, further highlight confidence in the long-term growth potential of the epoxy resin market.

Growth in Construction, Coatings, and Infrastructure Upgrades

The United States continues to invest heavily in infrastructure development, commercial construction, and public sector upgrades, creating a favorable environment for epoxy resin consumption. Epoxy coatings are widely used to protect concrete floors, steel structures, pipelines, and storage tanks from corrosion, abrasion, chemicals, and extreme weather conditions. These coatings extend asset life, reduce maintenance costs, and enhance operational safety, making them a preferred choice in industrial and commercial projects.

Sustainability considerations are also influencing market dynamics, with growing adoption of low-VOC and environmentally compliant epoxy formulations. Decorative epoxy flooring systems are gaining popularity in residential, commercial, and institutional buildings due to their aesthetic appeal, durability, and ease of maintenance. These systems provide seamless finishes that last for decades, making them cost-effective over the long term. The growing preference for functional yet visually appealing surfaces continues to drive epoxy resin demand across construction and renovation projects nationwide.

Expanding Use of Composite Materials in Automotive and Aerospace

The adoption of advanced composite materials is accelerating in the U.S. automotive and aerospace sectors, significantly driving epoxy resin demand. Epoxy-based composites offer superior strength-to-weight ratios, fatigue resistance, and thermal stability, making them ideal for high-performance applications. In the automotive industry, these composites are used in lightweight body panels, structural components, and electric vehicle battery systems, supporting improved efficiency and safety.

In aerospace manufacturing, epoxy composites play a critical role in aircraft fuselage sections, wings, interior components, and structural reinforcements. These materials reduce overall aircraft weight, enhance fuel efficiency, and increase payload capacity. The growing emphasis on electric vehicles, hydrogen fuel systems, and next-generation aircraft technologies further strengthens epoxy resin consumption. Product innovations introduced by companies such as Huntsman Corporation underscore the ongoing development of advanced epoxy systems for high-pressure and high-performance applications.

Volatility in Raw Material Prices and Supply Chain Pressures

Despite strong growth prospects, the U.S. epoxy resin market faces challenges related to raw material price volatility and supply chain disruptions. Key feedstocks such as bisphenol-A and epichlorohydrin are derived from petroleum, making their prices sensitive to crude oil fluctuations, refinery constraints, and geopolitical uncertainties. These factors create cost pressures for manufacturers and complicate long-term pricing strategies.

Global supply chain disruptions have also affected the availability of curing agents, additives, and specialty chemicals used in epoxy formulations. Small and medium-sized manufacturers are particularly vulnerable due to limited sourcing flexibility and lower bargaining power. Managing cost volatility while maintaining product quality and competitiveness remains a key challenge across the industry.

Environmental Concerns and Regulatory Restrictions

Environmental sustainability is an increasingly important issue influencing the epoxy resin market in the United States. Traditional epoxy resin production has faced scrutiny due to VOC emissions, toxic by-products, and the environmental footprint of synthetic raw materials. Regulatory authorities have introduced stricter standards related to chemical formulation, emissions control, and workplace safety.

Compliance with these regulations often requires significant investment in cleaner technologies, reformulation efforts, and alternative raw material sourcing. While bio-based and eco-friendly epoxy resins are gaining attention, their higher costs and performance limitations can restrict widespread adoption. Balancing regulatory compliance, environmental responsibility, and cost efficiency continues to shape strategic decisions across the epoxy resin value chain.

United States DGBEA Epoxy Resin Market

DGBEA epoxy resins represent the largest resin category in the U.S. market due to their well-balanced performance characteristics. These resins offer strong adhesion, high mechanical strength, and excellent chemical resistance, making them suitable for a wide range of applications. DGBEA-based systems are extensively used in coatings, adhesives, composites, and electrical encapsulation.

Their compatibility with various curing agents allows flexibility in formulation for construction flooring, marine coatings, automotive parts, and industrial maintenance applications. DGBEA resins are valued for their durability, corrosion protection, and thermal stability, supporting long-term performance in demanding environments. As industries continue to require reliable thermosetting polymers, DGBEA remains a preferred choice across U.S. manufacturing sectors.

United States Aliphatic Epoxy Resin Market

The U.S. aliphatic epoxy resin market is growing steadily due to superior UV resistance, color stability, and weathering performance compared to traditional aromatic systems. These properties make aliphatic epoxies ideal for outdoor and high-visibility applications, including clear coatings, decorative flooring, automotive refinishing, marine exteriors, and architectural surfaces.

Although aliphatic epoxy resins typically command higher prices, their long-term durability and resistance to yellowing justify their use in premium applications. Demand is increasing in commercial construction, sports flooring, and specialty coatings where appearance and environmental exposure are critical considerations.

United States Solid Epoxy Resin Market

Solid epoxy resins are widely used in the United States due to their stability, long shelf life, and suitability for powder coatings and high-durability applications. They are commonly applied in corrosion-resistant coatings for appliances, pipelines, metal furniture, and automotive components. Solid epoxy-based powder coatings offer excellent abrasion resistance, chemical stability, and strong adhesion.

In electrical and electronics manufacturing, solid epoxy resins are used for laminates, circuit boards, and insulation materials due to their heat resistance and structural integrity. The industry-wide shift toward solvent-free and environmentally friendly coating technologies further supports demand for solid epoxy systems.

United States Epoxy Resin Paints and Coatings Market

Paints and coatings represent one of the largest application segments in the U.S. epoxy resin market. Epoxy coatings provide superior protection for steel structures, concrete floors, pipelines, machinery, marine vessels, and storage tanks. Their resistance to chemicals, moisture, and mechanical wear makes them essential in industrial and infrastructure applications.

Epoxy flooring systems are widely used in hospitals, warehouses, manufacturing plants, and commercial spaces due to their hygiene, durability, and ease of maintenance. Infrastructure modernization projects, including bridge rehabilitation and water treatment facility upgrades, continue to drive demand. Advances in low-VOC and hybrid epoxy technologies further strengthen the outlook for this segment.

United States Epoxy Resin Electronic Encapsulation Market

Epoxy resins play a critical role in electronic encapsulation by protecting sensitive components from moisture, vibration, dust, and thermal stress. In the United States, epoxy-based potting and encapsulation materials are widely used in semiconductors, transformers, sensors, LED systems, automotive electronics, and renewable energy inverters.

The rapid growth of electric vehicles and domestic electronics manufacturing has increased demand for high-purity epoxy encapsulants. Their excellent dielectric strength and thermal conductivity enhance device reliability, efficiency, and safety, reinforcing epoxy resin’s importance in modern electronics.

United States Epoxy Resin Building and Construction Market

The building and construction sector remains a major consumer of epoxy resins in the United States. Epoxy flooring systems are favored for industrial plants, hospitals, and public facilities due to their seamless finish, durability, and low maintenance requirements. Structural adhesives and repair compounds based on epoxy are essential for bonding concrete, steel, and composite materials in infrastructure projects.

Epoxy waterproofing and protective coatings prevent moisture intrusion and extend the life of critical structures. Decorative epoxy applications are also gaining popularity in residential construction for countertops and interior design elements. Ongoing infrastructure renovation and modernization projects ensure steady demand for epoxy resin in construction.

United States Epoxy Resin Consumer Goods Market

The consumer goods segment has witnessed growing use of epoxy resins in DIY crafts, home décor, furniture design, and small-scale manufacturing. Consumers use epoxy to create river tables, jewelry, resin art, decorative items, and waterproof coatings. Its ability to cure into a clear, durable, and glossy surface aligns well with contemporary design trends.

The rise of social media tutorials and online creator communities has increased awareness and adoption of DIY epoxy kits. Home renovation projects, including garage flooring and countertop refinishing, further support growth in this segment. Versatility and customization potential continue to drive consumer interest.

United States Epoxy Resin Aerospace Market

The aerospace industry is one of the most significant consumers of epoxy resin in the United States. Epoxy-based composites and adhesives are critical for manufacturing lightweight aircraft components, including fuselage sections, wings, and interior structures. These materials offer exceptional strength-to-weight ratios, fatigue resistance, and thermal stability.

Demand for advanced epoxy materials is increasing with growth in commercial aviation, defense manufacturing, and space exploration initiatives. Epoxy resins support fuel efficiency improvements and compliance with stringent safety standards, making them essential to next-generation aerospace engineering.

Regional Outlook of the United States Epoxy Resin Market

California represents one of the strongest epoxy resin markets due to robust construction activity, advanced electronics manufacturing, and emphasis on sustainable materials. New York’s continuous infrastructure maintenance and commercial development sustain steady demand for epoxy coatings and flooring systems. Washington State benefits from aerospace, maritime, and technology sectors that rely on high-performance epoxy formulations. Arizona’s fast-growing construction industry and harsh climate conditions drive demand for durable epoxy coatings and flooring solutions.

Competitive Landscape of the United States Epoxy Resin Market

The U.S. epoxy resin market is moderately consolidated, with major players focusing on innovation, sustainability, and capacity expansion. Key companies include BASF SE, Covestro AG, DuPont de Nemours Inc., Hexion Holdings Corporation, and Olin Corporation. These companies compete through product development, strategic partnerships, and regional expansion, shaping a dynamic and competitive market outlook through 2034.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness